It’s Maintenance Time! How a Digital Floor Plan Can Improve System Maintenance and Reduce TCO

- Sales

- Design

- Installation

- Service

- Maintenance*

There are hidden costs with nearly anything we purchase in life. With the installation of systems and technology comes the responsibility of keeping it maintained. For complex systems such as electronic security, audio visual and information technology, the maintenance of installed elements is an everyday task and a cost that should be considered in the total cost of ownership, sometimes referred to as TCO.

In order to avoid commonly occurring malfunctions or break downs, systems need to be proactively maintained. In the case of security cameras, if they are not maintained and a camera breaks and surveillance comes to a halt, there is risk of video not being captured and evidence lost in the case of an incident. Thus, there is more at stake than just the fact that a camera is broken.

The challenge for maintenance is that systems often involve a multitude of different elements, components and devices. In other words, there are a lot of moving parts! Keeping track of all of the pieces to maintain can become overwhelming. The key is for everyone to be on the same “as-built” plans for any project so that the time it takes to maintain a system is reduced while providing reliability and scalability across tens or hundreds of sites or projects.

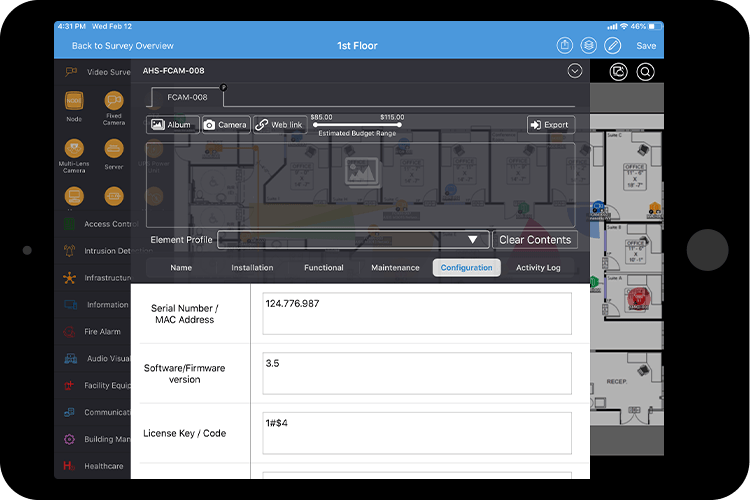

System Surveyor streamlines the maintenance process. It puts the maintenance team on the same digital floor plan and “as-built” records as the implementation team and project managers who initially installed the system.

Follow these tips using System Surveyor to be a step ahead in the maintenance process:

- Following installation: under the maintenance tabs, make notes on when elements are due for upkeep or maintenance.

- Utilize the different tabs for notes on each aspect of maintenance under the attributes tab for each element.

- Take photos (and annotate them) to indicate any areas of an element that could lead to a malfunction or breakdown, thus clarifying where on which element needs attention.

This concludes our series on tips to using System Surveyor to simplify the life cycle management of systems.

Now, with a better understanding of how to maximize the utility of System Surveyor, your team can use the tool to it’s full potential. Try it on up to 10 surveys.