Eman Taylor has been with System Surveyor since the start: he was the company’s first official full time employee. He started out supporting customers and being a jack of all trades. Now he leads the company’s product management team and plays an integral role on the leadership team. In this month’s post we share his insights on how System Surveyor is making a real difference, enabling system integrators and technology directors to create decision-ready security system designs —faster and more accurately than any other method.

We break down Eman’s observations into four steps in the system design workflow and the role of digital system design to streamline the process.

1. Gathering Requirements & Site Information

Maureen: You often talk about the system design workflow as an interrelated four-part process. Can you tell us about the first piece of the puzzle?

Eman: Absolutely! Over the years we’ve observed a fairly consistent workflow that has improved with digital system design versus manual processes.

The first step is about gathering the right information and requirements for a customer or stakeholder at their physical buildings or parking lots. In the industry, this is typically done at the site survey or site walk. That means people go out on site to capture the information about where devices would need to be physically placed and installed in order to be effective.

What we know is that how well a system integrator captures the right requirements and site information during the site survey is perhaps the single most important variable in the project’s outcome. The domino effect of garbage in could equal garbage out. The status quo of manual processes to capture this information isn’t great. In fact, a surprising number of people still map things out on a literal napkin (or maybe a paper floor plan if they’re lucky) and use a cell phone to capture pictures. It’s wasting a lot of time and risking their project margins..

But until people see an alternative, the status quo remains in place.

Maureen: That’s true Eman, can you share more about what happens at a site survey and how it’s improved with System Surveyor?

Eman: Definitely. One of the most important things to capture in a site survey are photos and device-specific information about how a device will be installed and implemented. For example, for a video surveillance camera or a sensor if a wall mount is needed versus a ceiling mount is important.

Everyone knows a picture is worth a thousand words. But before we came along most integrators were taking pictures with their phones. Those photos were stored in their camera roll and weren’t tied to anything concrete about the site. Once they returned back to the office, they had to try and relabel those photos — assuming they could remember where they took them and which device is associated with each picture. It’s been a huge headache for them.

At this site survey phase, System Surveyor customers use the mobile app on an iPad or Android tablet. They take the tablet with our software app on site in an offline mode (not while on the network) which makes gathering photos with context dramatically easier. When they take a photo using the app, it automatically gets associated with the digital floor plan and device without an additional step at the office. This saves hours of time back at the office. Even more importantly, it is more accurate than our memory of the location.

With this level of detail and accuracy coming out of the site survey, they’ve already done the heavy lifting.

With all of these amazing, context-specific photos, they would get back on a reliable Wifi network and upload or synchronize it to the cloud for the next step.

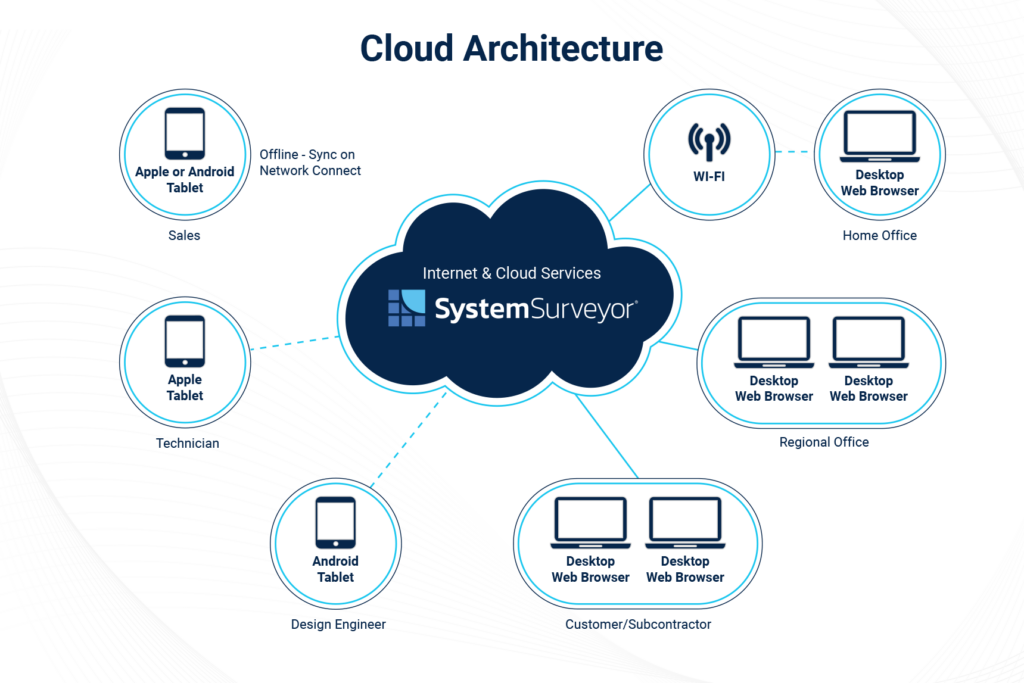

As a bit of background, here is how to think about the System Surveyor software platform. It is a cloud-based application with a companion mobile tablet app for use in the field.

2. Design Clean Up at the Office

Maureen: Once they get back to the office, how is the design clean-up process different with System Surveyor?

Eman: Depending on the project size, some System Surveyor users can create a detailed, accurate system design and automated bill of materials before they even leave the client site, which is huge. But most users still choose to bring that design “home” to the office for a bit of clean-up and polish.

Either way you’re still coming out ahead because with System Surveyor, you’re working through that last bit of finesse in hours, rather than days or even weeks.

As I suggested at the end of Step 1, “bringing it to the home office” is actually synchronizing the information gathered on the app to the cloud and accessing System Surveyor back at the office from a laptop or computer via a web-browser.

Oftentimes, the design is already 70% completed but not quite ready for the proposal. The good news is that this clean up is faster and more accurate than the manual method of moving to clean up.

A few things that happen at this point of clean up are the following:

- Based on the photos, the user can select products more specifically. As an example, maybe they did a drag and drop of a generic fixed video surveillance camera and with some additional thought or expert advice, they can now get more specific about what brand product and model number would be needed and specify it.

- Duplicate devices quickly. At this clean up phase, they often fill out other device needs to complete the design. This is automatically creating a visual system design and an automated bill of materials. Perhaps the site survey gathered enough for a baseline door access control system but this piece allows for an additional 10+ or more doors.

- Add cabling infrastructure or IT needs to support the system that would make the system design operational.

Here’s what we see at this phase, while some salespeople can take it to this point, often they will need an engineer, vendor or estimator’s assistance on the design. That brings us to the next step. Inviting colleagues to design together and collaborate.

3. Sharing & Collaborating

Maureen: What’s unique in the next phase and again why is it different from manual methods?

Eman: Once the design cleanup is done, there’s still plenty of collaborating left to do. What I see here is team members getting on the same page within an organization and between teams. Now they can see and work from the same information, which drastically improves quality and saves a lot of time.

At this stage, instead of emailing around out of date, hand annotated PDF floor plans, you can invite in and share the system design with team members, subcontractors, vendors, and end users. With System Surveyor as the foundation for the project, all interested parties can collaborate visually, in real time, inside a system design that’s built to scale based on real floor plan measurements.

Maureen: We’ve definitely seen more new video surveillance cameras and intrusion detections systems that have the opportunity to use AI and machine learning, it does matter where and how devices are installed. Otherwise, again garbage in/garbage out. For many integrators, this is new technology and they’ll need input from their favorite manufacturer partner.

Eman: Exactly, and these are a few of the key features that I see in use at this stage:

- Guest User feature: You can invite your customers onto a project, and they can see all that data in real time, giving them visibility into the design and a better opportunity to understand the system you’re building for them. If they see a red flag, they can voice it now — not later after the money’s been spent and the holes have all been drilled.

- Survey Comment Feature: They can instant message in System Surveyor and point out where they have questions. This has been a wildly popular feature to create faster, more accurate collaboration among teams and partners.

- Easy Share a Link: Allows you to share the survey design with a customer to see if you’re on the right track without exporting into PDF.

Maureen: Thanks Eman, that has been one of the biggest surprises around the new use cases of collaboration. Tell us more.

Eman: We talk about the “three-legged stool” to deliver solutions to customers. It turns out that we see a lot of new use cases between system integrators, manufacturers, and their corporate and campus customers. It is less siloed than before. Because everyone’s working from the same set of data and in the same visual sandbox, the results are better and more accurate.

In fact, we have seen Manufacturers really get on board. They are providing what we call “Element Profiles” which are their catalogs for more better intelligent drag and drop design to an automated bill of materials. This Manufacturer Partner Program has grown over the past few years and it’s creating better collaboration to speed up time to decision-ready proposal. It turns out that’s in the best interest of everyone involved to increase the velocity of high quality projects.

4. Proposals & Reporting

Maureen: As we move onto step four, it’s time to send a completed proposal to the customer or for end users, to the board or approvers or stakeholders. What’s the difference here?

Eman: The two biggest differentiators here are speed and accuracy: how quickly can you deliver a decision-ready proposal, and how accurate can you make that proposal? Every round of revisions slows down the sales process and lessens your likelihood of making the sale. That is a lost opportunity cost for an integrator. Our customers tell us they need to have accurate proposals out in a day or two, not weeks.

The top things that I see in this phase of the process:

- Using the Element Profiles to automate a bill of materials for the products and accessories.

- Providing a quality, professional design and BOM report with the integrator’s logo. It helps them look great and trusted when they are proposing a $100k project.

- Exporting not only the good looking PDF but also an Excel report makes the post sales or ordering process faster and more accurate. This is important to delivering on time and on budget.

- Creation of a digital as-built for ongoing system life cycle management.

Maureen: And can you talk about the value of a digital as-built?

Eman: Sure. Many customers are also generating a digital as-built for life cycle management and maintenance.

For example, one customer was ready to refresh camera hardware and thought they needed 30 cameras. But he pulled up their digital as-built and saw 50 cameras documented in System Surveyor. He was able to easily go in and confirm the 50 cameras with the new On-Screen Totals feature and get the budget and the order right the first time.

They can also plan for inspections, maintenance, IP addressing and other needs for the systems with better visual management.

Maureen: Eman, thanks for the time today and for your insights. Any parting thoughts?

Eman: Thanks for the opportunity. We continue to learn more about the needs of our user community and encourage feedback. I’m excited that this software can help many of the newcomers who have joined the industry. For those who do not have decades of experience, System Surveyor can help them be productive quickly and guide them to designing systems. With what we see in the growth of the industry, I am excited to see more people jump on board.

Aemmanuel “Eman” Taylor Bio

Eman Taylor is Product Manager with a wealth of experience and a passion for driving innovation in the technology sector. Currently serving as the Product Manager at System Surveyor, Eman has been an integral part of the company’s growth and success for the past seven years. Eman’s journey in the tech industry began after graduating from Texas A&M University, where he earned a degree in Psychology. Throughout his seven-year tenure at System Surveyor, Eman has played a pivotal role in helping with customer success and overall product strategy.

Maureen Carlson is co-founder and president of System Surveyor, the leading digital platform for physical-security site surveys and system design. With 25 + years in B2B SaaS and security technology, she leads the go-to-market and operations with a top notch team. Under her leadership, System Surveyor has grown into an industry-defining software used worldwide to streamline system design, enable collaboration, and raise the bar for security and technology professionals. Maureen enjoys building relationships in the industry and user community to build sustainable, high growth business. In her spare time in beautiful Austin, you’ll find her spending time outdoors, on a tennis court, reading or with family and friends.